Are you finding the Download Step 7 MicroWin V2.7 ? Find Motion Wizard S7-200 PLC Smart? In industrial automation, motion control plays a pivotal role in ensuring precise and efficient machine operations. Siemens’ S7-200 Smart (using Step7 Micro/WIN) and S7-200 (programmed with TIA Portal) are popular PLC systems designed for such tasks. This article delves into the equivalent subroutines (functions) in Motion Wizard between these two platforms, helping engineers transition seamlessly or choose the best fit for their projects.

Overview of Motion Control Subroutines

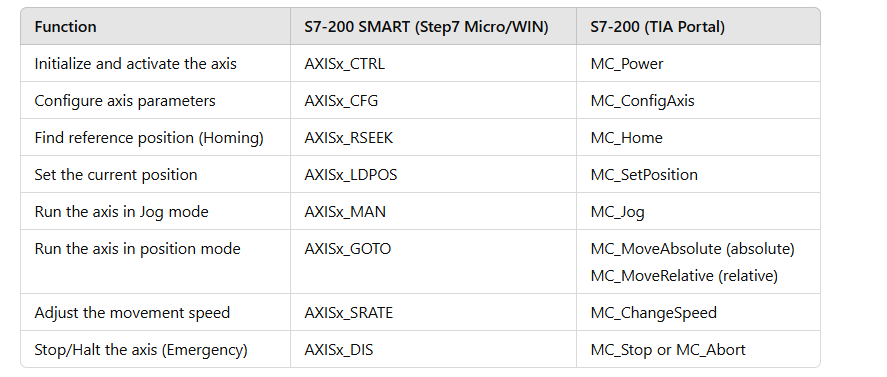

Both the S7-200 Smart and S7-200 platforms offer specialized subroutines or blocks for motion control. While S7-200 Smart uses pre-built subroutines like AXISx_CTRL or AXISx_MAN in Step7 Micro/WIN, TIA Portal employs standardized PLCopen Motion Control blocks such as MC_Power and MC_MoveAbsolute. These functions enable engineers to control motion axes effectively, whether for basic positioning, speed control, or advanced motion profiles.

Step-by-Step Comparison of Subroutines

Step 1: Axis Initialization

- S7-200 Smart:

AXISx_CTRL - TIA Portal:

MC_Power

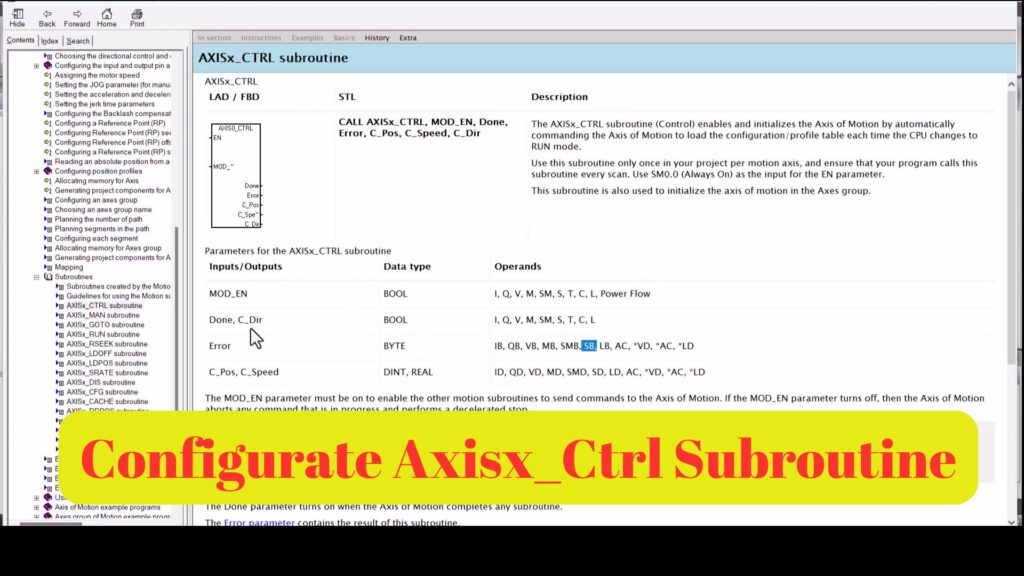

The AXISx_CTRL in Step7 Micro/WIN corresponds to the MC_Power block in TIA Portal. Both are used to initialize and enable the motion axis, ensuring it is ready for operation.

Step 2: Manual Jogging

- S7-200 Smart:

AXISx_MAN - TIA Portal:

MC_MoveJog

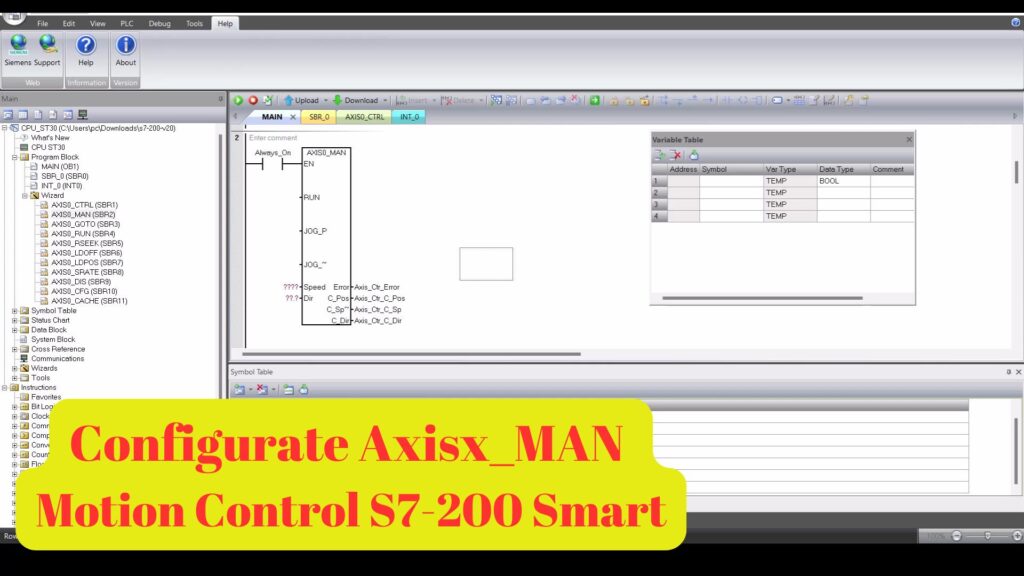

AXISx_MAN allows manual jogging of the axis, providing control to move the motor in positive or negative directions at a defined speed. The equivalent in TIA Portal, MC_MoveJog, performs the same function, enabling manual movement for setup or troubleshooting.

Step 3: Velocity Mode Operation

- S7-200 Smart:

AXISx_RUN - TIA Portal:

MC_MoveVelocity

The AXISx_RUN subroutine in S7-200 Smart can be likened to MC_MoveVelocity in TIA Portal. This function enables continuous motion at a fixed speed without targeting a specific position.

Step 4: Targeted Positioning

- S7-200 Smart:

AXISx_GOTO - TIA Portal:

MC_MoveAbsoluteMC_MoveRelativeMC_MoveHome

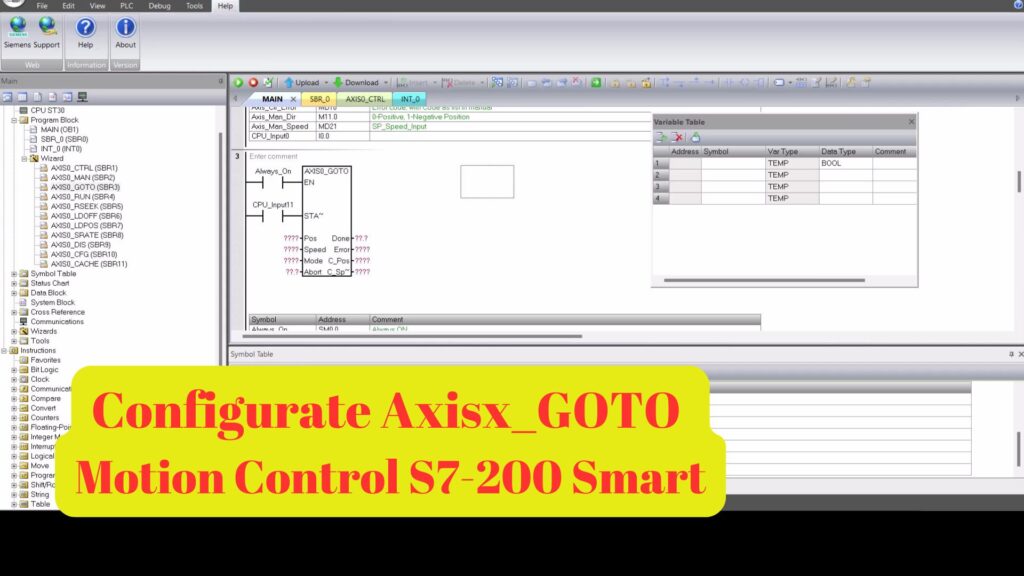

The AXISx_GOTO subroutine supports absolute, relative, or homing movements. In TIA Portal, this functionality is divided into three distinct blocks:

MC_MoveAbsolutefor moving to an exact position.MC_MoveRelativefor movement by a defined offset.MC_MoveHomefor homing the axis to a reference point.

Step 5: Command Execution via Table

- S7-200 Smart:

AXISx_CACHE(or equivalent custom logic) - TIA Portal:

MC_CommandTable

In S7-200 Smart, implementing command tables often requires custom programming or leveraging the AXISx_CACHE subroutine. TIA Portal simplifies this with the MC_CommandTable block, allowing predefined commands to execute sequentially.

Step 6: Controlled Stop (Halt)

- S7-200 Smart:

AXISx_DIS - TIA Portal:

MC_Halt

To stop motion safely, S7-200 Smart uses AXISx_DIS, while TIA Portal employs MC_Halt. Both ensure a controlled deceleration and halt of the axis without abrupt stops, preserving mechanical integrity.

Key Differences Between S7-200 Smart and S7-200 in TIA Portal

- Programming Environment:

- S7-200 Smart relies on Step7 Micro/WIN, a simpler and more traditional programming interface.

- S7-200 with TIA Portal utilizes a modern, integrated environment with extensive motion control libraries.

- Standardization:

- TIA Portal supports PLCopen Motion Control standards, ensuring compatibility across various Siemens PLCs.

- S7-200 Smart subroutines are proprietary and tailored specifically for the S7-200 Smart hardware.

- Flexibility and Scalability:

- TIA Portal offers advanced functions such as multi-axis synchronization and seamless integration with other Siemens devices.

- S7-200 Smart is ideal for smaller, standalone motion control applications.

When to Choose S7-200 Smart or S7-200 (TIA Portal)?

- S7-200 Smart:

- Best for simple motion control tasks with fewer axes.

- Ideal for engineers familiar with Step7 Micro/WIN.

- Suitable for cost-sensitive projects.

- S7-200 with TIA Portal:

- Recommended for advanced motion control applications.

- Perfect for projects requiring standardized PLCopen Motion Control.

- Scalable for systems with multiple axes and complex requirements.

Download V2.7 and V2.8 Trial Step 7 MicroWin Software and Equivalent Subroutines in Motion Wizard: S7-200 Smart (Step7 MicroWin) vs. S7-200 (TIA Software)

Looking for the best trial software for your automation projects? Whether you’re working with the S7-200 Smart or the S7-200 (TIA Software), the V2.7 and V2.8 trial versions of Step 7 MicroWin offer a great starting point for your programming and motion control tasks. And the best part? You can download these trial versions at no cost—just like grabbing a cup of coffee or a slice of cake!

What is Step 7 MicroWin?

Step 7 MicroWin is a comprehensive software suite designed for programming Siemens S7-200 PLCs. With the Motion Wizard feature, it makes it easy to implement motion control in automation tasks. This software helps in the creation and manipulation of motion profiles, allowing for sophisticated control of industrial machinery.

Key Features of Step 7 MicroWin:

- Programming Flexibility: MicroWin allows you to program both the S7-200 and S7-200 Smart series PLCs with ease.

- Motion Control: With the Motion Wizard, you can define motion profiles and control servo and stepper motors with ease.

- Subroutines for Efficient Programming: MicroWin enables the use of equivalent subroutines, which are essential for simplifying and speeding up your code development.

- Trial Version Availability: Versions V2.7 and V2.8 provide a trial opportunity, giving you full access to the software’s features for a limited time to explore all its functionalities.

S7-200 Smart (Step7 MicroWin) vs. S7-200 (TIA Software)

- S7-200 Smart (Step7 MicroWin): This version is ideal for simpler projects, offering ease of use and compatibility with older PLC models. It supports a range of automation applications, including basic motion control tasks.

- S7-200 (TIA Software): The newer TIA (Totally Integrated Automation) version allows for integration with modern Siemens equipment and provides more advanced features for larger, more complex systems.

Both versions offer powerful functionalities and can be downloaded and tested for free. The decision between the two depends on your specific project needs and the type of PLC hardware you are working with.

How to Download Step 7 MicroWin V2.7:

To get your hands on these amazing trial versions, visit the official website at vohauipr.com. On the site, you will find the links to download both V2.7 and V2.8 versions of the Step 7 MicroWin trial software, as well as helpful guides on installation and usage.

Download Process:

- Visit vohauipr.com.

- Navigate to the “Download” section on the homepage.

- Choose either V2.7 or V2.8 of the Step 7 MicroWin trial software.

- Click the download link and follow the installation instructions.

- Once downloaded, you can start programming and testing your automation solutions with the full suite of tools provided by the software.

Why Choose the Trial Version?

The trial versions of Step 7 MicroWin V2.7 and V2.8 are perfect for engineers and programmers who want to test out the software before committing to a full purchase. It allows you to evaluate its features—such as motion control, programming ease, and integration with Siemens PLCs—without spending a dime!

In conclusion, downloading the V2.7 and V2.8 trial versions of Step 7 MicroWin software from vohauipr.com is a simple and free way to explore the world of industrial automation. Whether you’re working on motion control or complex PLC programming, these trial versions will offer you all the tools you need to succeed.

So, go ahead and grab your free trial today—it’s as easy as enjoying a cup of coffee or a slice of cake!

Conclusion

Understanding the equivalent subroutines between S7-200 Smart and S7-200 in TIA Portal is essential for selecting the right platform and optimizing motion control performance. While both systems provide robust solutions for motion control, TIA Portal stands out for its flexibility, scalability, and adherence to industry standards. Engineers should evaluate their specific project needs to make an informed decision.

Leave a Reply